SOLUTIONS

Realible Measurement for Flow and Particle Size With Years of Experience. Contact Our ExpertsOur Solutions

SONARtrac® Flow Monitoring Systems

SONARtrac® systems from CiDRA provide non-intrusive, maintenance free flow and entrained air measurements with non-drifting industry-leading precision. Using patented passive SONAR technology, they clamp onto the outside of pipes, eliminating the need for process interruption, pipe penetration, or regular maintenance.

These systems deliver true volumetric flow and gas-void fraction (GVF) data, even in the harshest slurry and fluid conditions. With no moving parts, no wear, and no need for calibration, SONARtrac® is trusted in critical processes across mining, water treatment, and power generation. Oldest installations have been running already for over 20 years without changes in performance and without any maintenance.

Key Benefits:

- Clamp-on, non-invasive installation

- High reliability and zero maintenance

-

Accurate in noisy, abrasive multi-phase flows

- Long operational life in industrial settings

- Immune to different types of solids (eg. magnetic materials)

- Provides multiple diagnostics suchs as: flow quality, entrained air, sound pressure levels, flow rate that help us analyse process disturbances

-

Can be optimized according to the actual flow model and material distribution at installation position. Other methods assume the flow model always to be that of turbulent water flow and the material distribution to be homogenous, which it with slurries in practice never is.

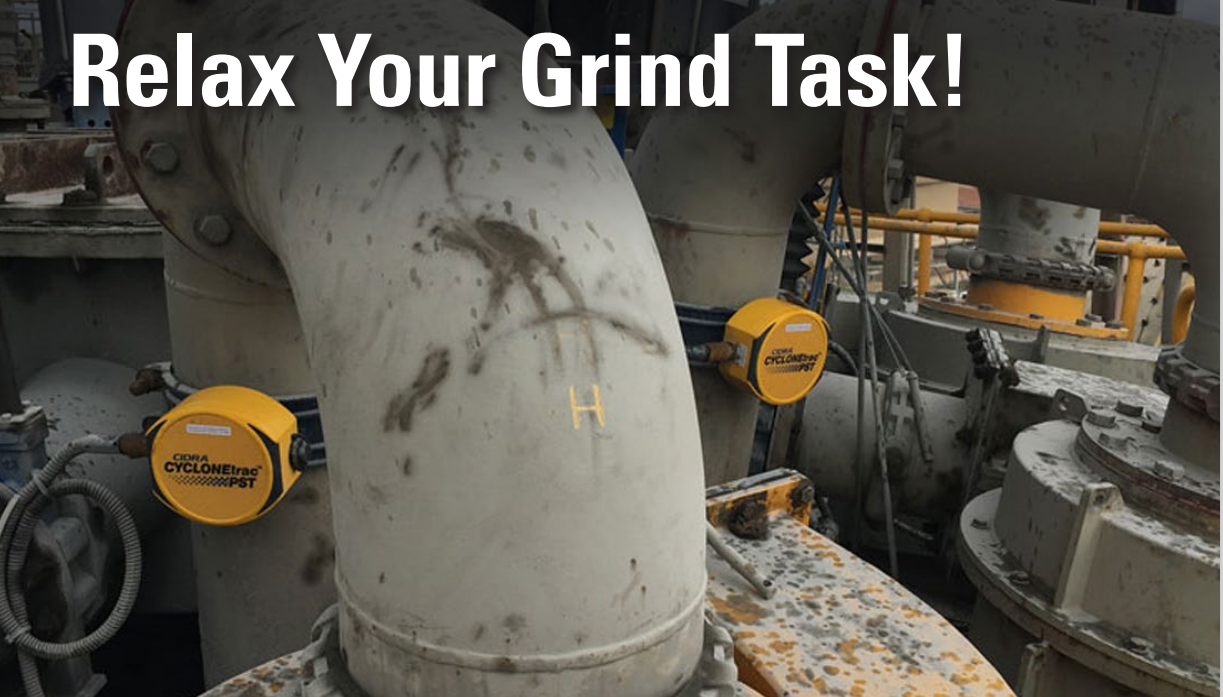

CYCLONEtrac™ Particle Size Tracking (PST)

CYCLONEtrac™ PST is a breakthrough solution for real-time particle size monitoring in grinding circuits. Installed on each hydrocyclone overflow pipe in the battery, it is the only system that can monitor up to five particle size limits from each individual cyclone with 4s intervals.

With PST in control of your grinding and classification process, you can optimize the particle size so that your next process stage and your grinding circuit work with higher efficiency leading to increased net metal production, better recovery and savings in energy and water consumption.

Key Benefits:

- Can follow up to 5 different particle size limits in real time from each individual cyclone.

- Our customers have gained up to 10% increase in net metal production with PST.

- No cyclone has ever gone to roping with PST in control.

-

Enables controlled increase in throughput with precise particle size management leading to increased net metal production.

-

Real time information on the operational performance of every hydrocyclone in the battery provides optimized classification, prevents oversize particle feeds to next process stage and minimizes the hydrocyclone maintenance costs as defects are immediately revealed.

Measurement Installation, Commissioning and Optimization

Beyond advanced hardware, Mesens combined with CiDRA deliver professional support for installation, configuration, commissioning and optimization of the delivered systems. Our team works closely with your engineers and operators to ensure seamless commissioning, process-specific calibration, and performance validation.

We help you get the most out of your equipment with data analysis, troubleshooting, and long-term system improvement plans. Whether integrating with existing infrastructure or scaling across multiple sites, we’re your partner for accurate measurement based process performance improvements.

Key Benefits:

- Expert installation tailored to your process

- Fast commissioning with minimal disruption

- Data optimization and performance validation

- Process analyses and support whenever you need it

WHY CHOOSE US

Reliable. Scalable. Industry-Proven.

Clamp-On, No Downtime

External installation means zero process interruption and no need to cut pipes or stop operations.

Built for Harsh Conditions

Designed for aggressive, abrasive, or corrosive flows—ideal for mining, wastewater, and energy.

Accurate in Complex Flows

Delivers precise readings even in flows with entrained air, solids, or noisy process environments.

Proven Across the Globe

Trusted in critical applications at hundreds of industrial sites worldwide.

Let’s Solve Your Measurement Challenge

Whether you’re upgrading equipment or improving process control, we’re ready to help.